We at Oak Hills Carton Co. will gladly assist you with deciding the most appropriate style for your project. There is a host of different carton styles from which to select!

If possible, send us a sample of a current carton that you are using. Alternately, you can provide us with a carton that you would like for us to mimic while making alterations specific to your particular application.

Factors to consider include:

- Contents of the carton

- Weight of the contents

- How the carton is to be displayed (orientation)

- Whether the carton will be hand loaded or machine loaded

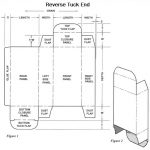

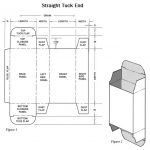

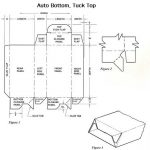

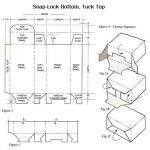

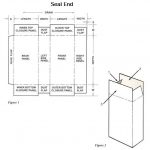

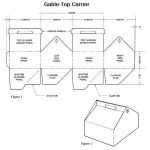

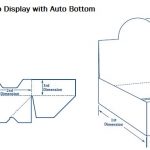

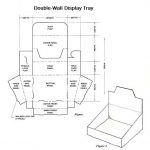

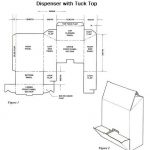

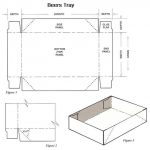

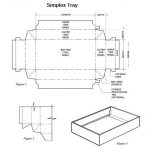

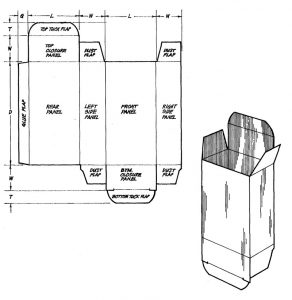

Our more popular carton styles include:

Click image to expand

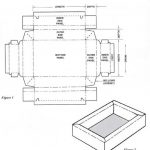

Guideline for Determining Dimensions

There is a proper sequence to describe the dimensions of a carton:

Length x Width x Depth

To determine the proper length, width and depth, place the carton facing you with the opening pointing up (as if the carton was to be filled from the sky).

- Length – the longest open end dimension from left to right

- Width – the shortest open end dimension from front to back

- Depth – the remaining dimension from top to bottom

When measuring always refer to the outside dimensions of the carton. Please measure from the center to center of the scores. Also, dimensions should be rounded to the nearest 1/16th of an inch.

FAQ's

What is the difference between a folding carton and a corrugate box?

We specialize in folding cartons. A folding carton starts as a sheet of paperboard measured in thousandths of an inch (i.e. .016, .024). It may or may not be printed. The sheet is then cut, scored, folded and glued to produce a folding carton.

A corrugate box is constructed with multi-ply fibers and is measured by flute size (i.e. B, C or E). Imagine yourself in a supermarket. The folding cartons are on the shelf and contain the product. The corrugate boxes are outer containers that help to protect the folding cartons and contents as they are shipped to the supermarket.

How do I measure a folding carton?

The proper sequence of dimensions is Length x Width x Depth. Place the carton in front of you with the open end up. Length is the longest open end dimensions from left to right. Width is the shortest open end dimension from front to back. Depth is the remaining dimension from top to bottom.

How soon can I get a price quote?

For most projects, once we know the carton style, dimensions, paperboard type including caliper, printing requirements and quantity, we can provide you with a price quote within 24 hours.

How long will it take to receive my folding cartons?

As a general rule, it will take 3 weeks for us to produce your custom unprinted folding cartons. Printed cartons will take approximately 4 weeks.

What carton sizes do you keep in stock?

We are a custom shop. We design and construct each project to the individual customer’s needs. We would be happy to design a folding carton that would be specific to you and your situation.

Is there a minimum order requirement?

In a word, NO. We will accept orders as small as one carton. However, please understand that the higher the requested quantity, the lower the per carton price.

Paperboard Types and Caliper

There are a variety of paperboards from which to choose. When selecting a paperboard, factors to consider include:

- the contents of the carton

- the weight of the contents

- the print (if any) that will be applied to the carton

- the interior color of the carton

- the desired “strength” of the carton

- the application of the carton (retail, warehouse, inner packer, etc.)

Here is a brief sampling of some of our more popular paperboards:

| Paperboard Type | Description | Uses/Sample Markets |

| Solid Bleached Sulfate (SBS) Virgin Board |

high quality, white throughout bright white background clean look |

high end packaging high quality graphics Cosmetics/Medical Industry |

| Solid Unbleached Sulfate (SUS) Virgin Board |

smooth white coated top smooth brown underside excellent strength & stiffness |

packaging for heavier products high end graphics Hardware/Auto Industry |

| Clay Coated News Back (CCNB) Recycled Board |

smooth white coated top good printability |

interior color is not an issue retail & warehouse applications Cereal/Crackers Light Hardware |

| Chipboard Recycled Board |

brown throughout poor printability |

strength & print clarity are not an issue warehouse applications inner packers layer pads/partition sets |

Paperboard is available in a variety of calipers (thickness). The unit of measure is thousands of an inch, also referred to as points. For example, paperboard that is .018″ is also known as 18 point. It is best to use a micrometer to accurately measure paperboard caliper.

It may be best to give us a description of what will be packaged in the carton and its intended use. We can suggest a specific paperboard and caliper.

Quantity

Carton prices are typically quoted as “price per thousand” ($/M).

Please understand that the higher the requested quantity the lower the unit price. This is due to the fact that the “set-up time” of the machinery is the same whether the quantity is 1 carton or 1000 cartons. Please see the chart below for a typical example.

| Quantity | Price per Thousand | Price per Piece |

| 1,000 cartons | $609/M | .61 each |

| 5,000 cartons | $201/M | .20 each |

| 25,000 cartons | $150/M | .15 each |

| 100,000 cartons | $129/M | .13 each |

To enjoy the economies of scale, it is beneficial to order as large a quantity as is reasonable. Perhaps it would be more economical to order a 3, 6, or 12 months inventory at one time.